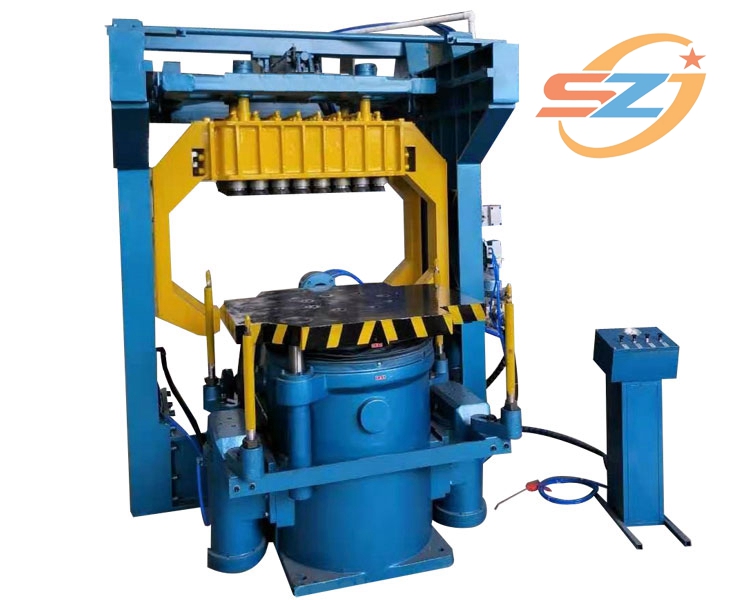

Hydraulic Multi-Piston Moulding Machine

Hydraulic Multi-Piston Moulding Machine

Hydraulic multi-piston moulding machine, can be used in automatic green sand casting production line or alone, 40-45moulds/h, divided into cope and drag, so it needs to be used in pairs, using air cushion type hydraulic multi-piston compaction, mainly suitable for castings with uneven surface, sand hardness is HB80-90 on average.Product Introduction

Hydraulic multi-piston moulding machine can be used in various foundry workshops for green sand up and down box moulding, which can be used as a single machine or formed into a mechanized assembly line.The machine adopts air cushion type full buffer pneumatic micro-vibration mechanism, so there is no special requirement for the foundation, the starting mold adopts connecting rod Synchronous shaft structure, pneumatic oil speed control, good synchronization of mold starting, speed control freely.

characteristics of Hydraulic multi-piston moulding machine:

1.Adopting pneumatic multi-contact compaction, there is no trouble of oil leakage; the ratio pressure is moderate, there is no special requirement for model sand, the number of contacts is large (24-72), which is suitable for complex modeling.

2.When this machine is compacting, the frame is not under force, but the table is hooked by four tie rods hanging down from the side of the multi-contact body, and the compaction is carried out with the downward extension of the multi-contact, if the contact, hook, sand box, model plate and table are regarded as a system, this compaction strength is internal force or called internal compaction.

3.Pressing shock compaction, the contact on the one hand, sand compaction, at the same time with the table together with the shock (and the rack from the rack, the rack is not subject to vibration). Therefore, the shock compaction effect is good, the sand hardness is high and uniform (the average hardness reaches 85~90, the value of B hardness meter), the sand eating volume can be as small as 20~30mm, the sand eating ratio reaches H:B=2~3, and the hardness of the vertical surface of the cavity can still reach above 80.

Hydraulic Multi-Piston Moulding Machine is composed of machine body, table, Hydraulic piston contact box, mould starting mechanism, pneumatic contact box and pneumatic piping system, etc.

1. The machine body is a solid hollow frame workpiece, the upper part supports the swivel arm press head part, when compacting, the swivel arm hooks the machine body so that the press force is borne by the machine body, the machine body and the shock mechanism are connected together with bolts, the swivel arm press head part, the press head is fixed on the swing arm, the press head has a screw elevator to adjust the distance from the press head to the sand box according to the height of the sand box.

2. The working table is made of ductile iron, cast and shaped, which is used according to the size of the sand box.

3.Hydraulic piston contact box is composed of multi-contact body, pneumatic multi-contact, and four pull hooks. The structure principle of pneumatic multi-contacts:The compaction inlet air is concentrated on the multi-contact body to the internal air cavity, while entering the lower air cavity of the fixed piston through a special channel on the fixed piston under the action of air pressure, which together make the contacts connected to the cylinder barrel go down and apply pressure to the sand type, whose pressure is the sum of d1 and d2 minus the area of d3 multiplied by the air pressure, so it can obtain a large pressure force.

4. The mould starting structure consists of two mould starting cylinders, connecting rod, balance shaft, mould starting table, mould starting rod, etc. When the mould starting cylinder starts, it drives the connecting rod, balance shaft and mould starting table to make the four top rods lift the sand box and start the mould at the same time.

5. Pneumatic piping system: the input compressed air, through the air filter to remove the water and impurities in the compressed air, and then through the oil mist injected lubricant, supply each pneumatic components and institutions, machine action by the hand-pull valve console to achieve.

6. Air supply and lubrication. Machine is by the air source for energy and oil to do lubrication to achieve the work. The size of the inlet pressure and the size of the oil volume are adjusted by the pressure reducing valve and oil regulating valve. The air source through the oil fogger according to the principle of siphon will be sucked into the pipeline, fog into the pipeline system for lubrication